A Comprehensive Guide to EGR Systems and Diagnostic Procedures

2023-07-04 by UDIAG

In the realm of internal combustion engines, optimizing performance and minimizing emissions are constant goals. One technology that plays a vital role in achieving these objectives is Exhaust Gas Recirculation (EGR) systems. This essay aims to provide a comprehensive guide to EGR systems and diagnostic procedures, covering their principles, types, benefits, diagnostic tools, maintenance, and troubleshooting.

I. Overview of Exhaust Gas Recirculation (EGR) Systems

EGR systems are designed to reduce emissions and enhance engine efficiency. These systems work by reintroducing a portion of exhaust gases into the combustion chamber. By doing so, they decrease peak combustion temperatures and limit the formation of nitrogen oxide (NOx) emissions. The components of an EGR system include the EGR valve, cooler, and associated control mechanisms.

II. Types of EGR Systems

There are various types of EGR systems employed in automotive applications:

- Passive EGR: This system utilizes the pressure differentials between the exhaust and intake manifolds to enable gas recirculation without the use of additional components.

- Low-pressure EGR: By employing a dedicated EGR valve and cooler, this system allows controlled recirculation of exhaust gases at lower pressure points in the engine.

- High-pressure EGR: In high-pressure EGR systems, exhaust gases are recirculated at higher pressure points, typically after the turbocharger, resulting in greater efficiency.

- Hybrid EGR: Hybrid EGR systems combine multiple techniques to optimize recirculation efficiency and tailor it to specific engine requirements.

III. Benefits of EGR Systems

The integration of EGR systems in engines yields several significant benefits:

- Reduced NOx emissions: EGR systems effectively mitigate the formation of NOx, a harmful pollutant that contributes to air pollution and smog formation.

- Improved fuel efficiency: By lowering peak combustion temperatures, EGR systems enhance fuel efficiency by reducing the energy wasted as heat and improving the engine’s thermal efficiency.

- Lower combustion temperatures: EGR systems help prevent excessive heat buildup, reducing the strain on engine components and potentially extending their lifespan.

IV. How to Diagnose EGR System Issues & Monitoring it with OBD-II Scanners

Diagnosing EGR system issues and monitoring its performance with OBD-II scanners is a crucial aspect of maintaining and troubleshooting the EGR system in your vehicle. Here is a step-by-step guide on how to diagnose EGR system issues and monitor it using UDIAG OBD-II scanners:

- Establish Communication:

- Communicate the UDIAG OBD-II scanner with the vehicle’s onboard computer system via VCI.

- Follow the instructions provided by the scanner to establish the connection.

- Ensure that your vehicle’s engine is turned off before communication.

- Retrieve Trouble Codes:

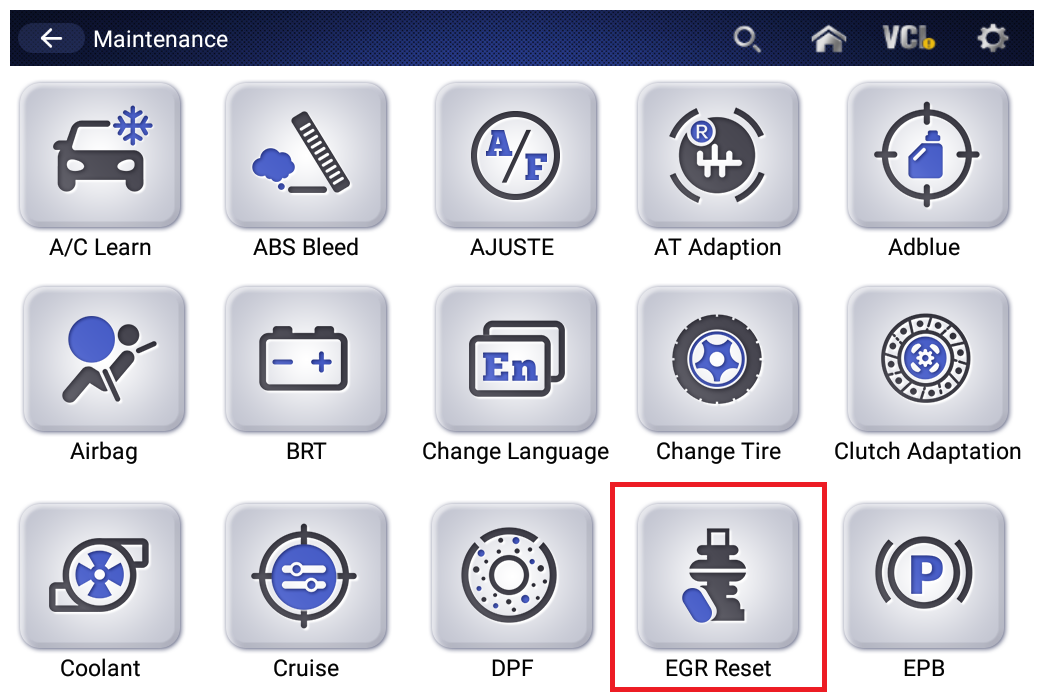

- Access the “Maintenance” menu on the UDIAG OBD-II scanner.

- Select the “EGR” to retrieve codes specific to the EGR system.

- The scanner will display any stored trouble codes related to the EGR system.

- Interpret the Trouble Codes:

- Refer to the scanner’s user manual or an online database to interpret the trouble codes.

- Each trouble code corresponds to a specific issue or malfunction in the EGR system.

- Note down the codes for further reference.

- Monitor Live Data:

- Access the “Live Data” menu on the OBD-II scanner.

- Look for EGR-related parameters such as EGR valve position, EGR flow rate, exhaust gas temperature, and intake manifold pressure.

- Monitor these parameters in real-time while the engine is running to observe their values and behavior.

- Compare Parameters to Specifications:

- Consult the vehicle’s service manual or manufacturer’s specifications to determine the correct operating values for the monitored EGR system parameters.

- Compare the live data values displayed on the scanner to the specified ranges.

- If any parameter falls outside the acceptable range, it may indicate a problem with the EGR system.

- Clear Trouble Codes (optional):

- If you have addressed and resolved the identified EGR system issues, you can choose to clear the trouble codes using the OBD-II scanner.

- Note that clearing the codes will also reset the vehicle’s readiness monitors, which will require some driving under specific conditions to reset.

By following these steps, you can effectively diagnose EGR system issues and monitor its performance using UDIAG OBD-II scanners. Remember to consult the vehicle’s service manual or seek our assistance for further troubleshooting and repairs if needed.

V. EGR System Maintenance and Troubleshooting

Regular maintenance is essential for optimal EGR system performance. Some common issues that can arise with EGR systems include clogged passages, malfunctioning EGR valves, or excessive carbon buildup. To troubleshoot these issues, technicians can employ diagnostic techniques such as visual inspection, functional tests, and data logging. Cleaning procedures, such as EGR valve cleaning and decarbonization, are vital for ensuring the longevity and efficiency of EGR components.

VI. Conclusion

Exhaust Gas Recirculation (EGR) systems are a critical component in the quest for efficient and environmentally-friendly internal combustion engines. By understanding the principles, types, benefits, diagnostic tools, maintenance, and troubleshooting associated with EGR systems, technicians and automotive enthusiasts can optimize engine performance, reduce emissions, and prolong the life of their vehicles. As technology continues to advance, staying informed about emerging diagnostic tools and procedures will be paramount in achieving the full potential of EGR systems and their contribution to a sustainable automotive future.