Car Diagnostic Scanner: Features, Benefits & Buying Guide

2025-04-24 by UDIAG

Introduction:

A car diagnostic scanner is a specialized tool for vehicle inspection and fault detection. It evaluates a car’s technical condition without disassembly, covering engine diagnostics, chassis inspection, body/accessory checks, and emission/noise testing. Designed for professionals and individual owners, these compact devices integrate advanced technology to provide real-time data analysis and multiple diagnostic functions.

Common Functions of A Car Diagnostic Scanner

-

Read Fault Codes: Retrieve error codes and repair guidance from the engine control unit (ECU).

-

Clear Fault Codes: Erase stored error codes from the system.

-

Live Data Stream: Monitor real-time ECU parameters.

-

Freeze Frame Data: Capture vehicle status during emission-related faults.

-

Sensor Tests: Access oxygen sensor monitoring results.

-

Vehicle Info Retrieval: Read VIN, CALID, and CVN data.

What are the Advantages of a Car Diagnostic Scanner

Sleek Design & Portability

Featuring a streamlined, ergonomic design with premium finishes, the scanner combines compactness and lightweight construction for enhanced portability. Its industrial-grade sunlight-readable display ensures clear visibility in outdoor environments, while upgraded internal components deliver a modern, tech-savvy aesthetic.

Enhanced Performance

Equipped with a high-speed processor and optimized software, the device ensures rapid data streaming, lag-free operation, and swift execution of commands (e.g., actuator tests). Enhanced system stability minimizes downtime, boosting diagnostic efficiency and workflow productivity.

Smart Automation

Automated VIN recognition eliminates manual input errors, while AI-powered diagnostics provide precise fault code analysis and guided repair solutions. Enjoy hassle-free wireless updates for new vehicle models, replacing outdated card-based upgrades and freeing technicians to focus on critical tasks.

Versatile Functionality

Beyond OEM-level diagnostics, it offers 25+ specialized functions—surpassing conventional tools—including EV system support, a real-time voltage monitor, and a built-in LED flashlight for low-light environments. These innovations address diverse real-world repair scenarios.

How to Choose a Car Diagnostic Scanner

Prioritize Reputable Brands

Opt for established brands renowned for advanced technology, system stability, and high accuracy. These devices deliver faster scans, reliable results, and durable build quality, minimizing long-term operational risks.

Match Features to Your Needs

Quick-Service Shops: Select scanners with core diagnostics plus specialized functions (e.g., ABS bleeding, battery reset) to expand billable services.

Complex Repairs: Invest in professional-grade tools with programming capabilities and full-system coverage.

Future-Proofing: Choose hybrid scanners compatible with both fuel-powered and electric vehicles (EVs) to handle growing EV demand cost-effectively.

Evaluate Update Agility

With annual vehicle tech advancements, prioritize brands offering timely software updates for new models, protocols, and repair databases. A car diagnostic scanner that evolves with the market maximizes ROI by avoiding frequent replacements.

Ensure Cross-Platform Compatibility

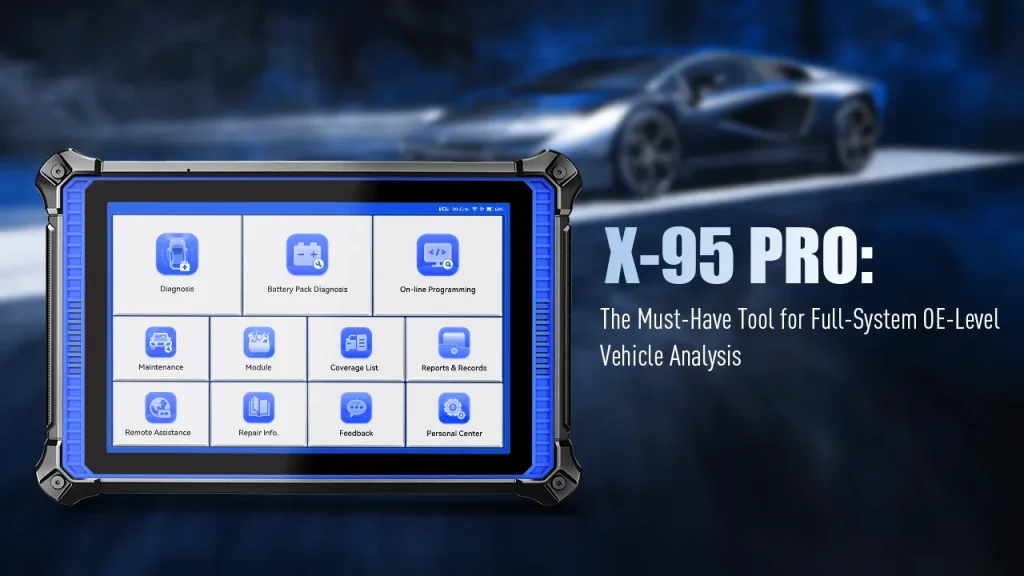

Avoid single-system tools. Opt for versatile diagnostic scanners like the Udiag X-95 Pro, which supports 120+ passenger cars, 70+ EVs, and 150+ heavy-duty vehicles across 41 maintenance functions, ensuring seamless integration with diverse workshop equipment.

Verify After-Sales Support

Robust technical assistance is critical. Confirm the manufacturer’s service network, response time, and availability of troubleshooting resources (e.g., hotlines, on-site support) to resolve issues swiftly.

Common Diagnostic Contents for Automobiles

Visual Inspection

Components Checked: Engine, undercarriage, electrical systems, steering components, and pedal mechanisms.

Key Assessments: Fluid levels (oil, coolant, etc.); leaks (oil, water, air, or electrical); visible damage/wear.

Safety Component Testing

-

Critical Systems:

-

Brakes: Performance evaluation via brake test benches.

-

Steering & Alignment: Wheel alignment and balance using alignment rigs and dynamic balancers.

-

Lighting: Beam intensity and alignment checks with headlight testers.

-

-

Tools: Side-slip testers, wheel balancers, and computerized alignment systems.

Powertrain Performance Analysis

-

Engine Diagnostics:

-

Ignition/Fuel Systems: Analyzed via engine performance testers.

-

Component Wear: Assessed through oil condition monitoring tools.

-

-

Drivetrain Evaluation:

-

Acceleration/Coasting: Measured using chassis dynamometers.

-

Power Output: Tested at the drive wheels for efficiency metrics.

-

Emissions & Noise Compliance

-

Exhaust Analysis:

-

Pollutants: CO, CO₂, HC, and NOx levels measured via gas analyzers.

-

Diesel Particulates: Smoke opacity tests for compliance.

-

-

Noise Control:

-

Decibel Levels: Tracked with sound level meters to meet regulatory standards.

-

Step-by-Step Guide to Using a Car Diagnostic Scanner

Device Preparation

-

Select a Compatible Scanner: Verify compatibility with your vehicle’s make, model, and OBD-II protocol (e.g., ISO 15765-4 for modern cars).

-

Update Software: Ensure the scanner’s firmware and databases are up-to-date for access to the latest diagnostic protocols.

Vehicle Connection

-

Locate OBD-II Port: Typically found under the dashboard near the steering column.

-

Link the Scanner: Securely plug the device into the 16-pin OBD-II port to establish communication with the ECU.

Diagnostic Process

-

Initiate Auto-Scan: Select the “Full System Scan” option to run a comprehensive check across all onboard modules (ECM, TCM, ABS, etc.).

-

Retrieve Fault Codes: Review Diagnostic Trouble Codes (DTCs) and their definitions (e.g., P0171 = System Too Lean).

-

Analyze Freeze Frame Data: Examine snapshots of engine parameters (RPM, load, fuel trim) captured at the time of fault occurrence.

Post-Diagnostic Actions

-

Clear DTCs Strategically:

-

Perform a pre-clearing scan to document all active/pending codes.

-

Erase codes only after addressing root causes.

-

Conduct a post-clearing scan to confirm resolution and check for recurring codes.

-

-

Generate Report: Export or print diagnostic results for repair records or technician collaboration.

Pro Tips:

-

For intermittent issues, use the scanner’s live data mode to monitor sensor outputs in real-time during test drives.

-

Activate bidirectional controls (if supported) to test actuators like fuel injectors or EGR valves.

Pro Tips for Maximizing Car Diagnostic Scanner Efficiency

The fault content is analyzed in combination with the fault phenomenon

The fault code query function of the fault diagnostic instrument can be used to scan the electronic control system of the faulty vehicle. In most cases, what is recorded for faults is not the cause of the fault. However, the content of the fault record provides the scope for determining the location of the fault. Combined with the fault phenomenon and other auxiliary checks, the fault can be quickly eliminated.

Analyze and discover the common causes of multiple faults

In the majority of cases, when performing fault queries using the fault code reading function, multiple relevant fault records are retrieved. Occasionally, these faults are not independent; instead, they may stem from an underlying issue or exhibit a causal relationship. By analyzing the stored data from this perspective and integrating it with other diagnostic methods and maintenance expertise, faults can be efficiently identified.

Make full use of the data stream query function

By querying the data stream, the control unit can retrieve and display specific values for the data information of relevant sensors and actuating elements, as well as their switch status information. Fully utilizing these data facilitates accurate fault analysis and judgment.

Attach importance to the meaning of data status information

The data information within the control unit, as read by the automotive diagnostic instrument, is presented in various formats and units of measurement. Comprehending the representation and significance of this data facilitates a more thorough understanding of the control unit’s operational status, as well as the information related to certain sensors and actuating components.

Conclusion

In conclusion, the car diagnostic scanner is a sophisticated vehicle fault detection device that enhances the efficiency, convenience, and simplicity of automotive repair work. Utilizing an automotive fault diagnosis detector enables rapid reading of fault codes and data streams, as well as conducting action tests on actuating elements. Should you desire a swift, convenient, and comprehensive diagnostic process for your cherished vehicle, please do not hesitate to contact us.